ZX Boring, Facing & Contouring Systems

Cogsdill’s ZX Tooling System provides the ultimate solution in terms of productivity, flexibility, and accuracy for machining large parts that require multiple operations. The ZX system can perform a variety of precision machining operations on horizontal boring mills.

ZX™ Systems

Making machine tool automation beautifully simple.

The Cogsdill ZX range of Contouring and Boring tools, allow relatively simple 2-axis CNC programs to perform a variety of machining operations, converting linear actuator motion into radial movement. Part changes can be accommodated quickly and easily with program changes.

Operations that were previously performed manually can be converted to CNC Control, thus improving productivity, accuracy, part to part repeatability and improved surface finish.

| Operations include: | ||

|

|

|

Machine tool requirements:

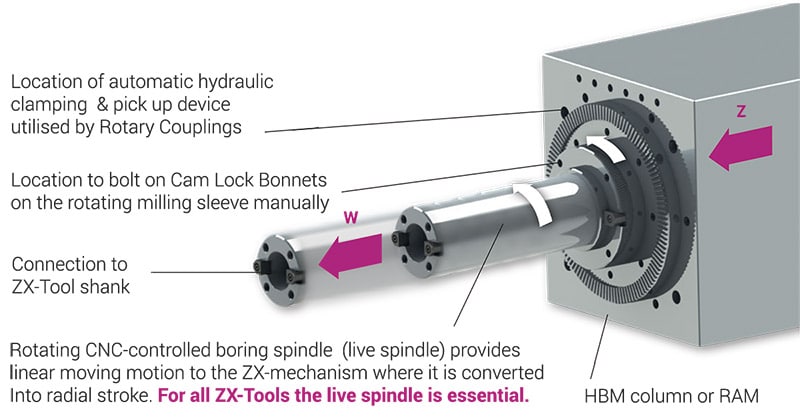

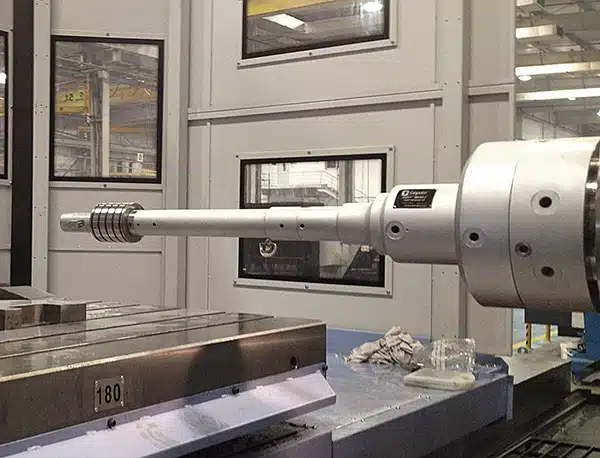

The ZX™ system requires the use of a horizontal boring mill with a programmable inner spindle that rotates in unison with the outer spindle, or milling sleeve. The axial movement of the inner spindle is converted within the tool into radial cutting stroke for diameter control. Movement of the table, or machine column, on a parallel axis controls the axial location of the cutting edge relative to the part. In most horizontal boring mills, these two axes are referred to as “W” and “Z”.

- Controlled inner spindle movement is converted into radial cutter movement

- Independently controlled column or table movement parallel to spindle

Compatible with:

and many others…

Operating principles

The ZX system is comprised of two basic styles of tools:

- Facing / contouring heads: featuring a single slide onto which various top tooling can be installed.

- Boring / contouring tools: used primarily in boring operations inside parts.

Regardless of head type, a proven actuation mechanism produces radial cutter movement. This sturdy design is based on the “sliding inclined wedge” principle for backlash-free operation; no sloppy gears or bell cranks are used. All parts are hardened and ground for lasting accuracy and durability.

Other benefits:

- Improved accuracy

- Improved repeatability from part to part

- Improved part quality

- Improved surface finish

- Extremely rigid design for roughing and finishing

- Backlash-free actuation mechanism

- Modular design for maximum application flexibility

- A wide array of solutions to suit a variety of applications

Many customers who have changed to the ZX System from conventional tooling report productivity increases of up to

500%

Examples of configurations machined using ZX tools:

O/D Grooving

O/D Tapers & Radii

Grooving

Back Counter Bore & Chamfering

Threading

O/D Threading

O/D Turning & Facing

Bottle Bore

Tapers & Radii

More flexibility. Extra support.

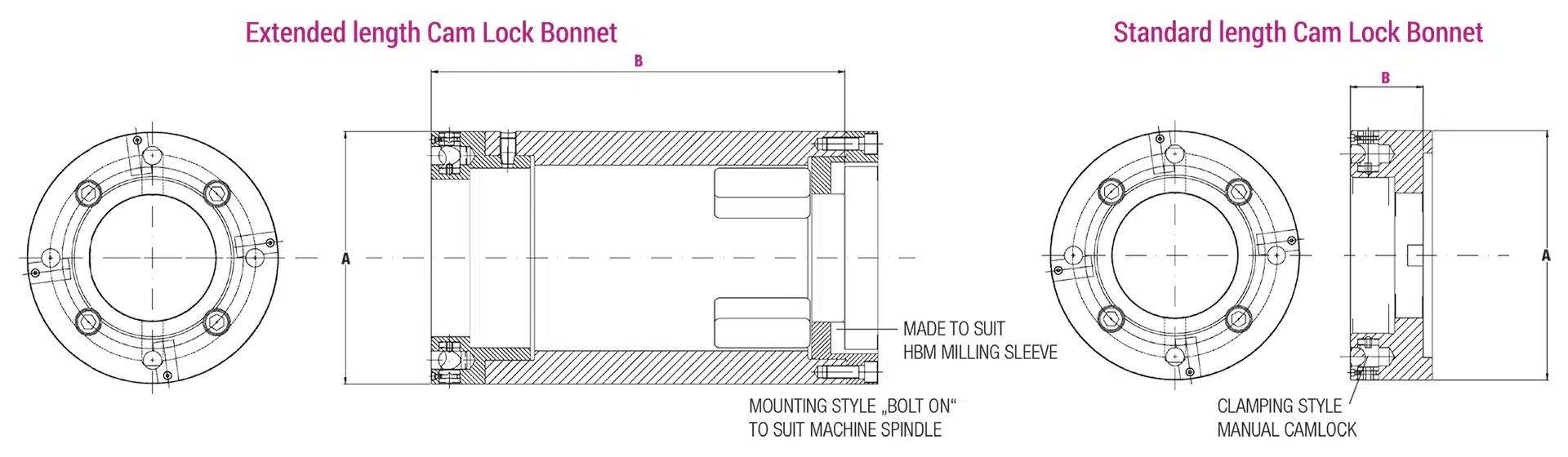

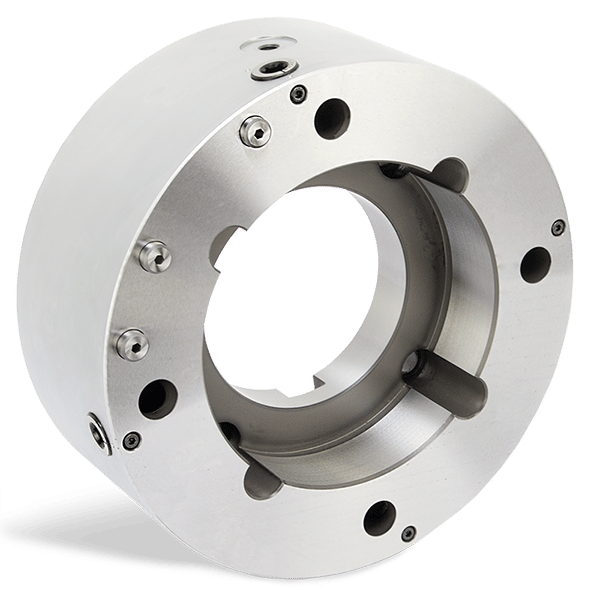

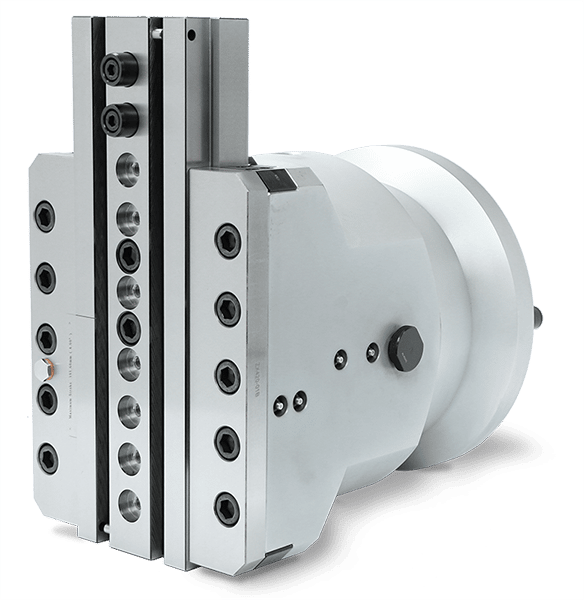

The ZX system features a quick release mounting device called a CamLock bonnet. The bonnet is precisely machined to fit the specific Horizontal Boring Machine (HBM) for which it will be installed. The bonnet bolts to the outer spindle of the machine and utilises our quick-release CamLock mechanism, which is designed with you in mind. It is the first integral part in our modular system (bonnet / head / slide adapter / cutter) and is designed to reduce downtime in production.

When the bonnet is installed it literally functions as part of the machine and offers a generous engagement surface for the ZX tool, providing maximum support and rigidity and eliminating loads on spindle bearings. CamLock allows for the swapping of the various heads and tools onto the bonnet with a simple marrying of four points and locking with an Allen Key. It’s available on all our ZX tooling systems and offers the ability to quickly change tooling applications with ease.

Enhancements available:

- Chip cover plates with wiper seals to keep the mounting surfaces clean

- Integral proximity switches to activate software on compatible machines

- Extended length bonnets are also available

Quick change. Easy glide.

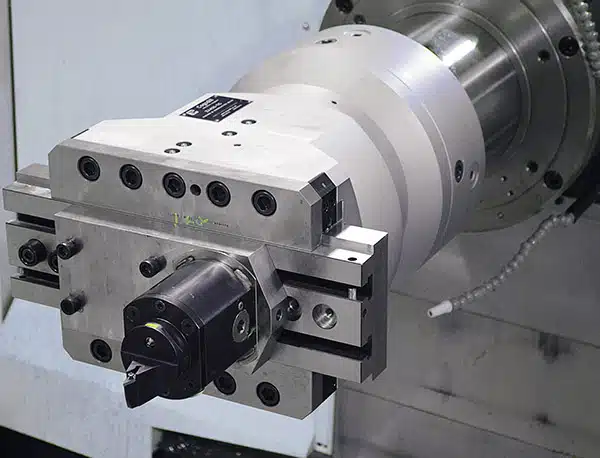

The ZX facing & contouring head offers the greatest versatility of all ZX tools. These heads have a single front-mounted tool slide onto which top tooling is located into qualified holes. This provides for repeatable set-ups and flexibility for varying machining applications, e.g. doing internal or external work. With appropriate top tooling, these heads can perform boring, facing, O.D. turning, grooving, taper boring, radius forming, chamfering, recessing and threading. The ZX concept is to do several functions via multiple passes from a single tool interface, which integrates with standard ISO tools. Large parts can be machined in one set-up without removing the work piece from the machine tool table.

- Ranges from 200mm to 900mm depending on end tool / requirements

- Internal coolant as standard

- Integrates with standard ISO tools

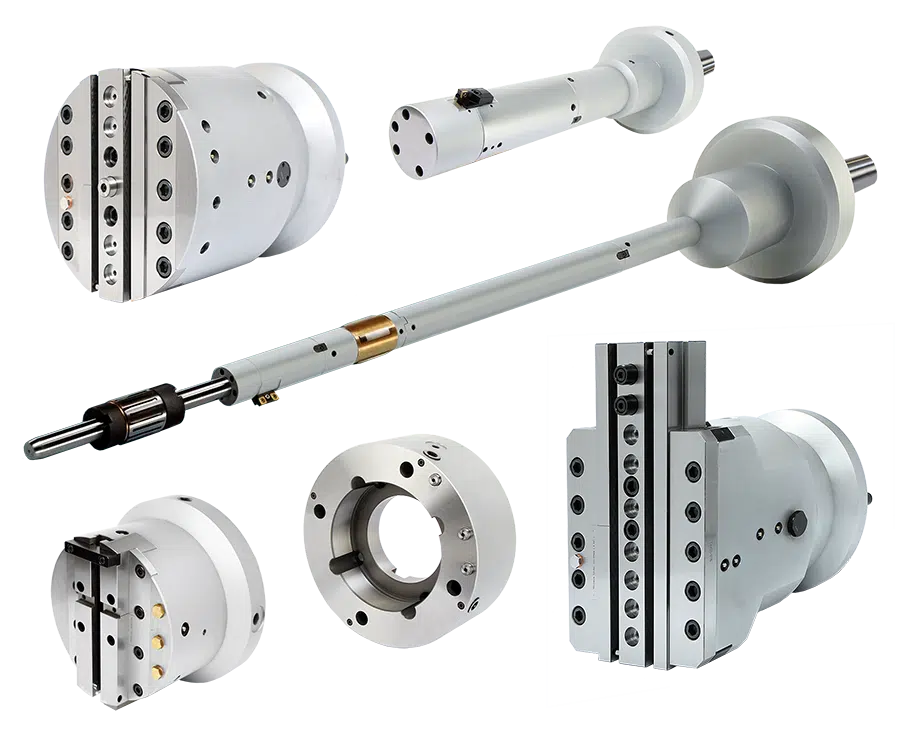

Your future. Fully automated.

Welcome to the next-wave in tooling innovation from Cogsdill.

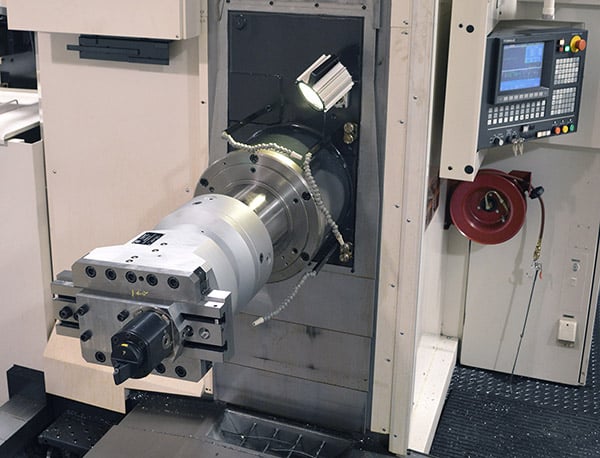

With more and more industry sectors rushing to take hold of the opportunities for enhancing the capabilities of their machine tools, we are finding an increasing desire to extend the capacity of conventional Horizontal Boring Mills (HBM) and multi-tasking machines. The desire is to broaden the machine’s scope by bringing additional flexibility and thus maximising efficiency.

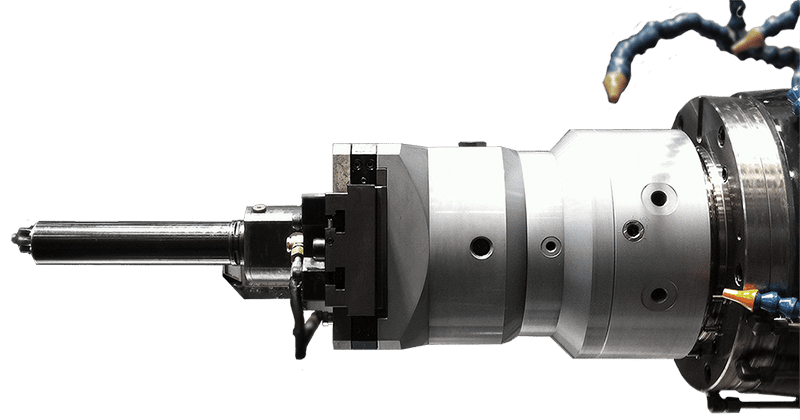

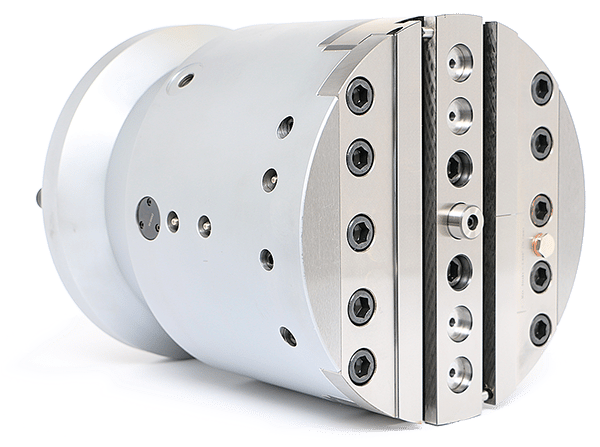

Furthermore, with some of these tools becoming increasingly larger in size, there has been a requirement to remove manual intervention altogether. As a result, we have introduced a new quick-change coupling system that uses hydraulic clamping. ZX Rotary Couplings – our latest interface development – are completely unique to Cogsdill and can remove the necessity of an operator and crane to load and unload the tooling, whilst vastly broadening the types of machine that can now utilise the ZX system.

ZX Rotary couplings provide a fully automated solution that can select different heads / boring tools depending upon the application. Utilising the latest hydraulic capabilities, the ZX system can synchronise in unison with your multi-tasking machine. When coupled with robotics, your tools can automatically be picked up and loaded from a complementary rail stack system.

Other benefits:

- Fast changeover: Think of it like a ‘pit stop’ for all your manufacturing requirements.

- Health and safety: Remove greasy manual intervention where things potentially slip.

- Wider industry applications: Oil and gas, mining, rail, aerospace, marine, etc.

- Broader machine spectrum: Soraluce, Mazak, DMG Mori, Doosan and many others.

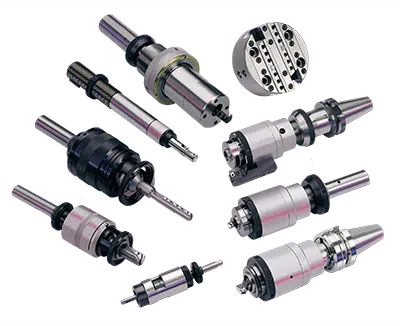

Facing & Contouring Heads

The Cogsdill ZX Facing & Contouring heads offer the Greatest versatility of all from the Cogsdill ZX Tooling range. These heads have a single tool slide; onto which top tooling is mounted into qualified locating holes. This provides for repeatable set-ups.

With appropriate top tooling, these heads can perform boring, facing, taper boring, radius forming, chamfering, recessing and threading. Large parts can be machined without having to remove the work piece.

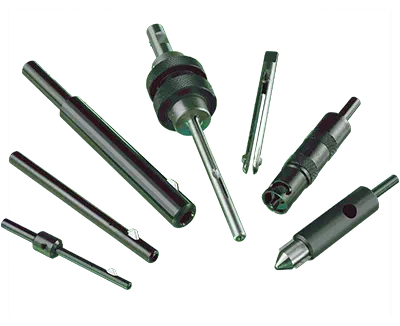

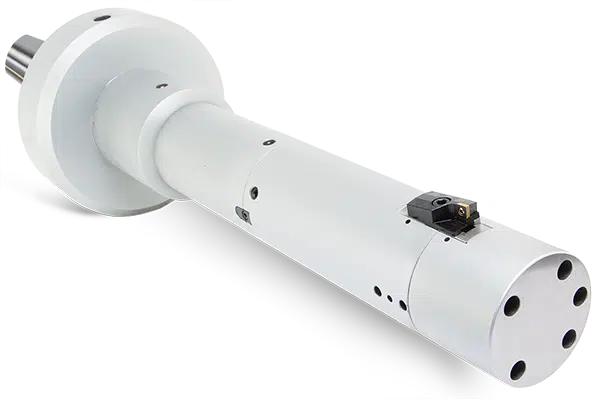

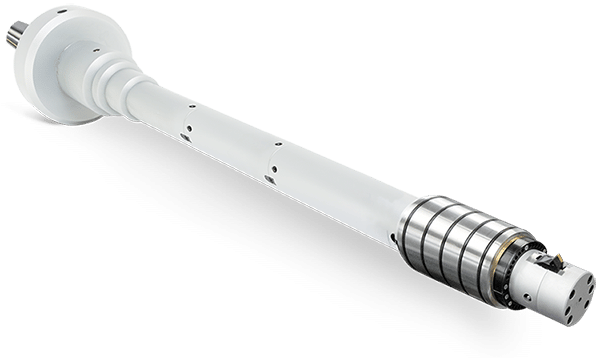

Modular Boring Tools

Cogsdill ZX Modular Boring Tools (MBT) offer versatility and economy when machining bores, counter-bores, tapers, threads and complex contours inside components over a wide range of diameters. These tools offer the highest cutting speeds and material removal rates available. The MBT Series is available in single-slide (MBT-S) and twin-slide (MBT-T) versions. All MBT tools feature 2:1 actuation ratio for easy programming.

Valve Seat Pocket Tools

Specially adapted ZX Modular Boring Tools feature piloted cutter support for use in machining seat pocket areas in oil valves and other extended reach applications. Valve seat pocket machining involves boring with severe interruptions. Internal chamfers, tapers, and faces are also common, as are long reaches through relatively small bores.

ZX Valve Seat Pocket Tools have enough stroke and strength to rough-machine preclad seat pocket cavities and, using the same tool, to finish-machine the pocket in Inconel after cladding. Non-clad pockets can also be machined. Seat pocket tools are commonly used in steel, stainless steel, and Inconel. All tools feature 2:1 actuation ratio for easy programming.

Bottle Boring Tools

ZX bottle boring tools enable a manufacturer to machine complex internal shapes, sophisticated bore transitions and undercuts. Generally used on HBM Machines, these tools can also be adapted to suit Deep-Hole-Drilling machines, Mill turn machines and Horizontal and Vertical lathes to produce internal extended reach cavities, seat pockets and bottle shaped contours including roughing and finishing operations in one set-up.

The ZX bottle boring tool is supported with a proven pilot system, either utilising a rotating O’ring pilot assembly, designed to keep coolant and chips away from the tool body or via coated carbide wear pads. The tools are designed to use ISO inserts within cartridges or directly fitted into the toolslide. The tools can be adapted for extreme pressure coolant systems, including Jetbreak®, to help with swarf removal.